How to make a jack plane

Practical Action

Place the two parts of the stock together with a small piece of scrap timber below the join.

Line up the two halves of the throat and position a clamp at each end so that the shoes are

above and below the join. This prevents the two pieces sliding across each other. Next, place

one clamp across the front, and another across the back, and tighten until some of the glue is

squeezed out of the joint. The first clamps can now be removed and placed on the back of the

plane. Check that the throat is still aligned. Wipe off the excess glue with a wet rag, and allow

it to set for six hours.

Planning the stock and truing up the throat

Plane the sides of the stock down to the gauge lines. Mark one side as the face side. Plane

the top and bottom of the stock square to the new face side. Use a 25mm chisel to true up

the front and back of the throat. Check that the frog is flat using a plane blade or a straight

edge.

Drilling the holes for the crossbar

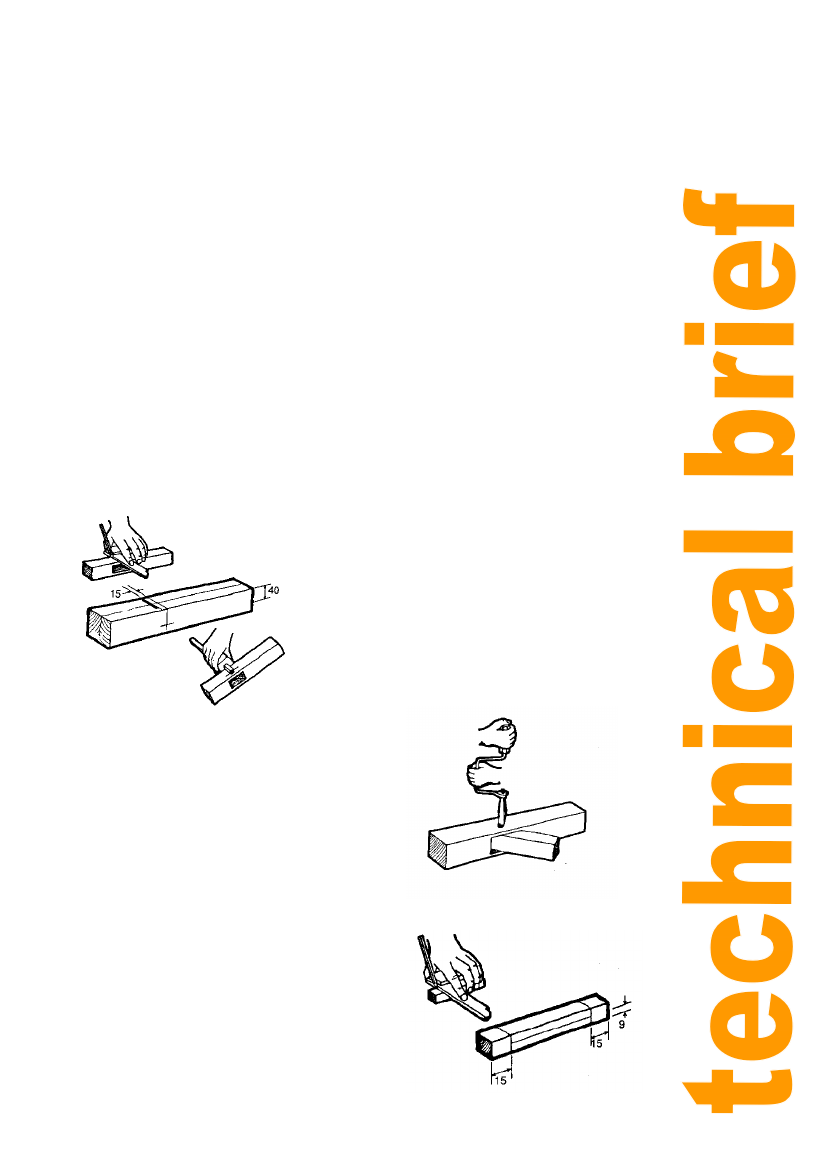

Square a line on the sole of the plane, 15mm behind the back of the mouth, and continue

this line on both sides of the plane.

Gauge a line on each side of the stock to meet

the pencil lines, 40mm from the sole. This

marks the centre of the holes for the crossbar.

To prevent the drill bit splintering the inside of

the throat, a piece of scrap timber, roughly

55mm x 50mm, should be planed to fit tightly

into the throat.

Place this piece of wood in the throat.

Centre an 18mm drill bit on the two lines just

marked and drill right through the cheek. Ask for

assistance to make sure the drill is square.

The hole on the other side of the stock is drilled in the

same way.

Making the crossbar

Take the 80mm x 18mm x 18mm piece prepared for

the crossbar.

Square lines all round the piece, 15mm from each

end, to mark the ends of the housing. Gauge a centre line on two opposite sides to mark the

depth of the housing.

Plane the crossbar to an octagonal section.

Fit the crossbar into the holes in the side of the stock.

Make a series of saw cuts down to the gauge line, and

chop out the waste with a chisel, first by driving the

chisel along the grain from both ends and then by

paring down across the grain.

6